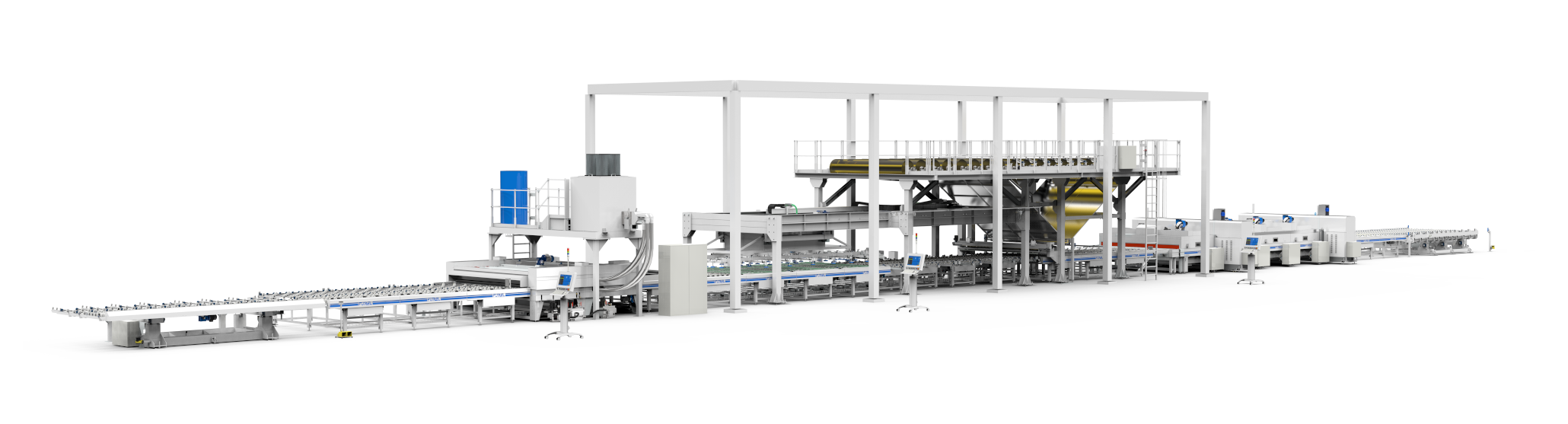

The lamination line Art. LL designed and engineered for the laminating of flat glass with various types of PVB interlayers. The line is comprised of various operational modules to clean, position and install PVB interlayers precisely and efficiently. The line is equipped with self-diagnostic software that identifies faults with codes, descriptions and images with an additional system to allow remote support.

The washing zone features a six-brush washing machine, equipped with a self-learning device for measuring glass thickness and automatically detecting Low-e glass types. An antistatic bar can be provided to prevent dust contamination.

A precision linear system that is equipped with suction cups to collect and transfer the glass sheet post the washing process.

Various types of PVB are stored and located in a distribution magazine situated within the application clean room. The positioning station is equipped with an automatic sheet centering system for the perfect alignment of glass and PVB.

The heating and pressing areas are made up of two temperature-controlled zones with two sets of pressing rollers. The ovens are equipped with electronic thermo-regulated resistors and work in combination with a forced air convection system.

The lamination line is specified with a tilting table, the weight capacity is 1.500 Kg.

The lamination line Art. LL can be equipped with a huge storage, capable of holding up to 10 PVB rolls, from which the product is automatically unwound to a special anti-static bar that prevents the deposit of dust particles.