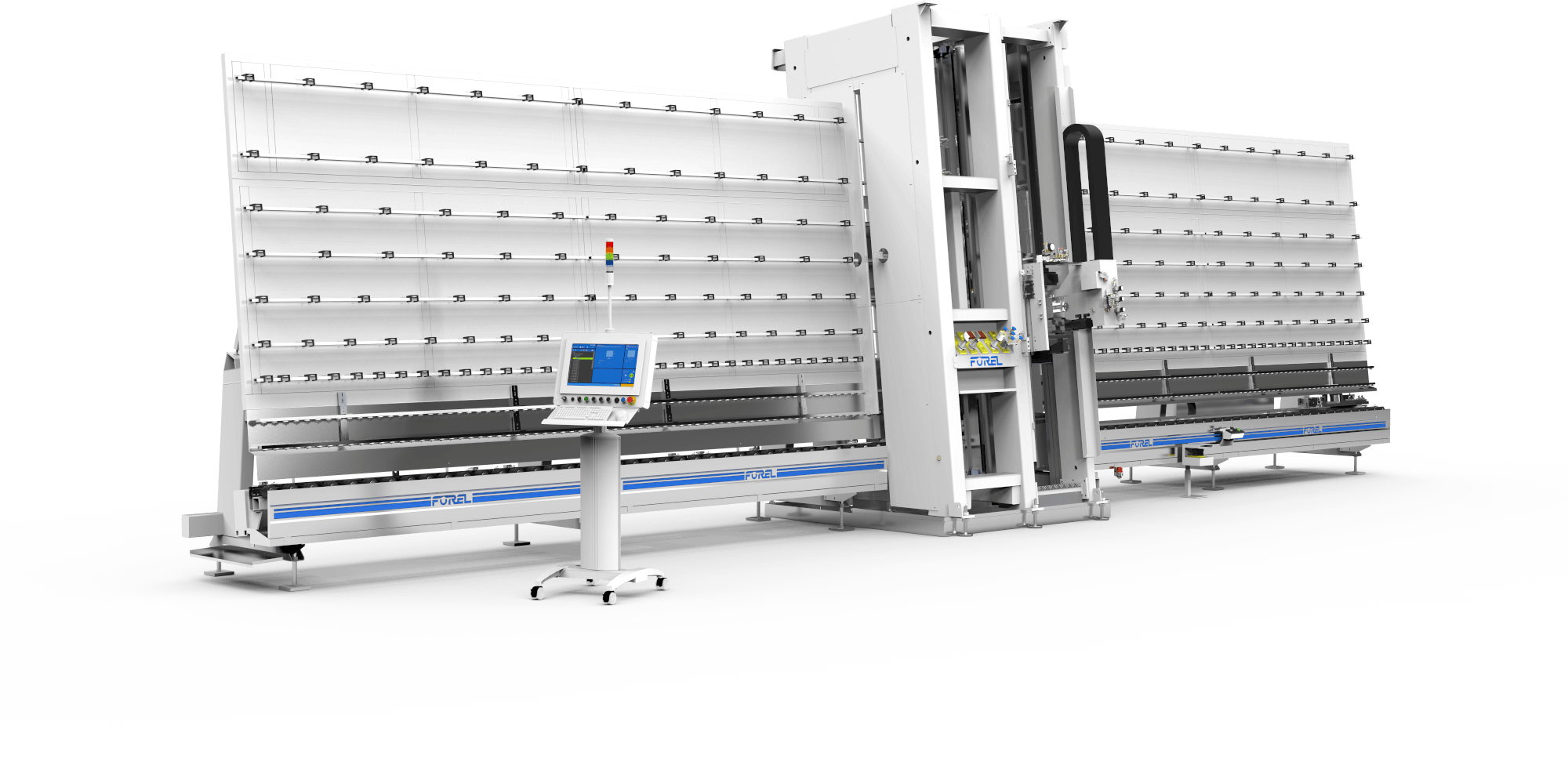

Enhanced with specific technical features that guarantee precision and stability are all critical aspects to achieve the desired result. Mounted to the precision-built structure are state of the art components to provide accuracy, stability and performance. The Art. DM vertical drilling and milling machine is an outstanding option for serious glass processing and offers seamless automation to a complex glass process. This module is usually combined with Art. EM edging machine and Art. WM washing machine to create a high-capacity fabrication line.

The Art. DM drilling and milling machine is equipped with

independent double opposing operating heads. Both

use an automatic tool change system, with 6 positions for the rear spindle and 8 positions for the forward spindle.

Art. DM is equipped with two sets of suction cups (both are patented).

The first bank of suction cups are fixed to the main superstructure ensuring that the glass pane is firmly gripped into position within the processing area.

The second set of suction cups are mounted close to the operating head and depending on the requirement, can be positioned by the operator independently. This set enhances the stability of the glass piece close to the working tool improving accuracy and quality.

During the drilling operation the secondary spindle can be positioned exactly opposite the primary spindle with an appropriate buffer tool: in this way, the drilling process of the glass sheet and the associated combined pressure is perfectly balanced between both tools.

The Art. DM is equipped with specifically designed CAD-CAM software for the acquisition and modification of the glass pane drawing. The software interacts with the machine for the creation of tool paths, optimised settings and process times.

Where needed an additional system of suction cups can be attached directly to the rear spindle, to ensure greater stability and protection during processing. The additional rear suction cups secure and then dispose of larger scrap pieces directly to the waste area avoiding any scrap collisions with the working piece.