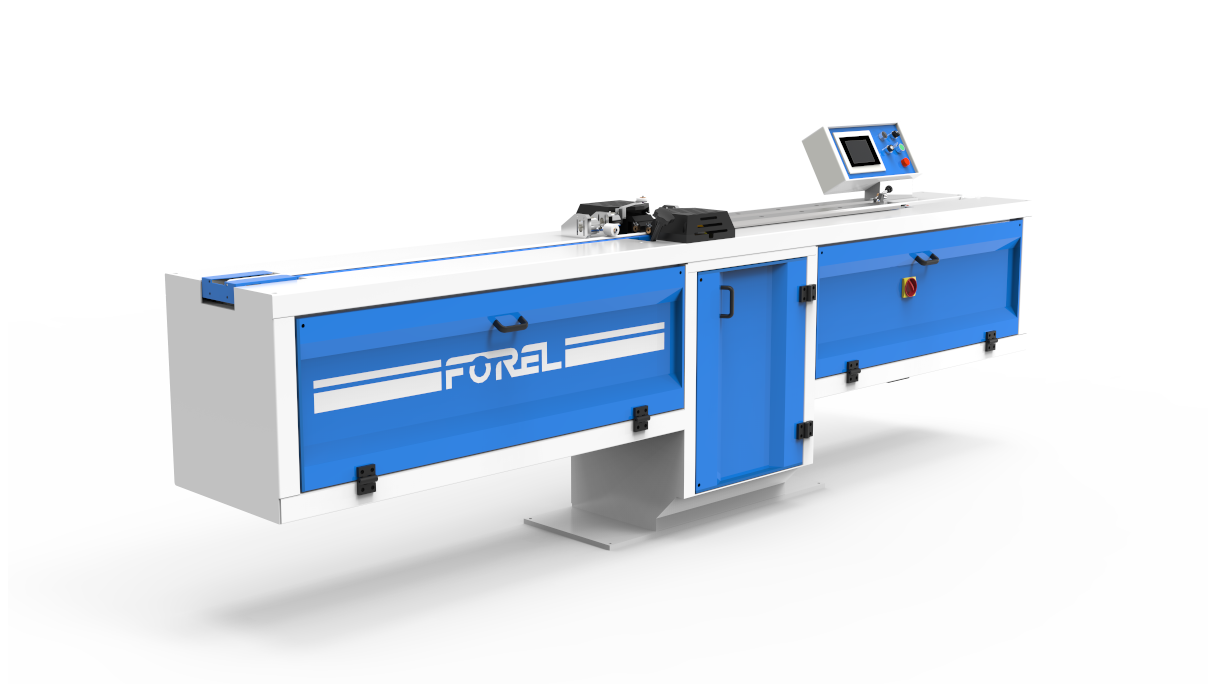

The Art. MB butyl extruder ensures full compliance with the most stringent standards required for the primary seal. The polyisobutyle (PIB) rubber is extruded through two separate dispensers and then applied via the application nozzles. The utilisation of a measured dozing system guarantees the uniformed distribution of the PIB around the entire perimeter (a special feature unique to Forel). The touch screen unit manages the automatic opening of the nozzles (width adjustment) and the positioning of the pre-extrusion guides, according to the selected spacer width value. The injection capacity (grams of PIB per linear metre) can be set directly. Art. MB can also apply PIB to shaped profile or Georgian bar frames, with the same accuracy and simplicity of operation. Preproduction heating of the product can be pre-set.