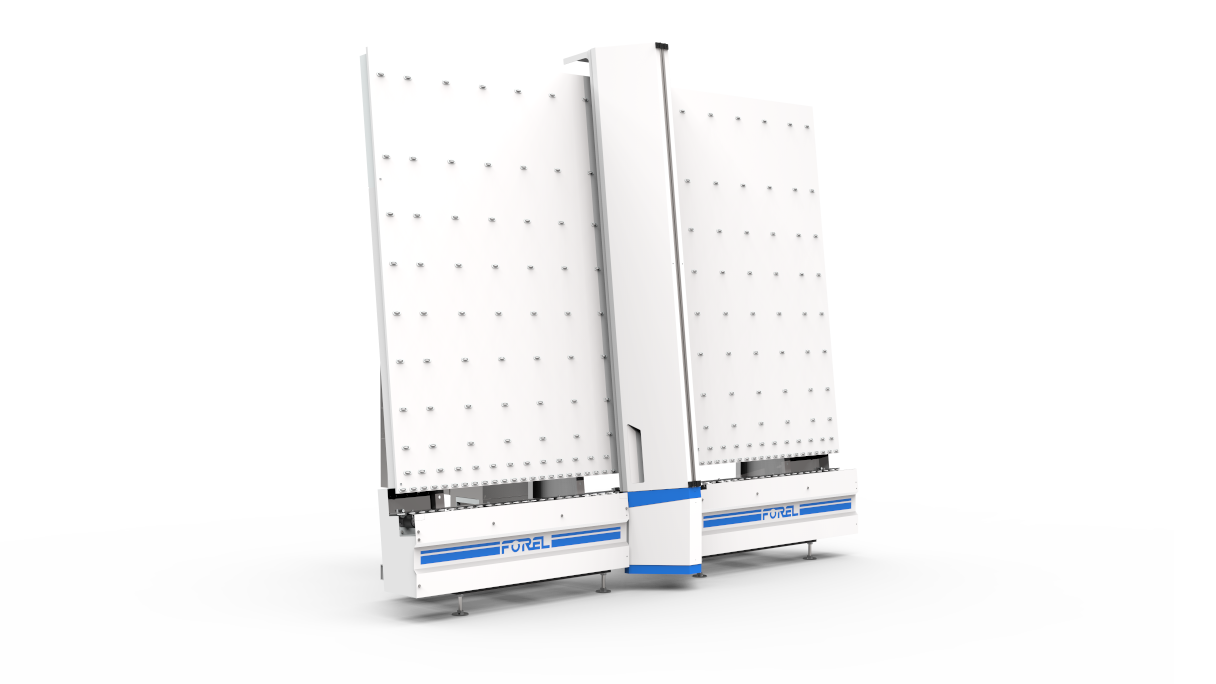

The Art. SQ is an inline digital quality control scanner that identifies and classifies surface defects on both side of a glass pane. Utilising proven scanning technology in combination with a specific light source, the device system logic locates and grades surface defects to assist line operators with quick quality resolution. Imperfections such as scratches, seeds, cracks and chips can be detected using a variable scale inspection slider, that can be tuned to specific standards by the operator. The scanner is normally mounted vertically to the exit conveyor of the glass washer which, allows for the entire glass piece to pass through the scanning zone. Due to the equipment’s versatility, this module can be fully integrating into an insulated glass production line without compromising productivity. The SQ can quality scan glass sizes of up to 6000 x 3300 mm with absolute precision in a totally non subjective way, crucial in the manufacture of large insulated glass units. All quality information relevant to the glass piece is scanned and archived internally but the file data can be exported and stored for post production analysis and record.

The Art. SQ can also be specified with an option of dimension control, again in real time the scanner detects the peripheral edge of the glass automatically mapping its size and shape. This information is particularly useful to ensure that all pieces within a sealed unit are of the same dimension and orientation. Shaped glass information can also be detected and the associated dimensional information sent to downstream platforms for immediate shape execution